Stainless steel wire has a wide range of applications in various industries, and the aerospace industry is no exception. In aerospace applications, stainless steel wire is used in a variety of ways due to its unique properties, including its strength, corrosion resistance, and durability. In this article, we will explore the uses of stainless steel wire in aerospace applications.

- Aircraft Wiring: Stainless steel wire is commonly used in aircraft wiring because of its strength and resistance to corrosion. The wiring must be able to withstand the harsh environment of high altitudes and changing temperatures. Stainless steel wire provides the necessary strength to support the electrical components and systems in the aircraft.

- Control Cables: Control cables are used to operate various systems within an aircraft, such as the landing gear and flaps. Stainless steel wire is used in these cables due to its high strength and resistance to fatigue, which is necessary to ensure the safety of the aircraft.

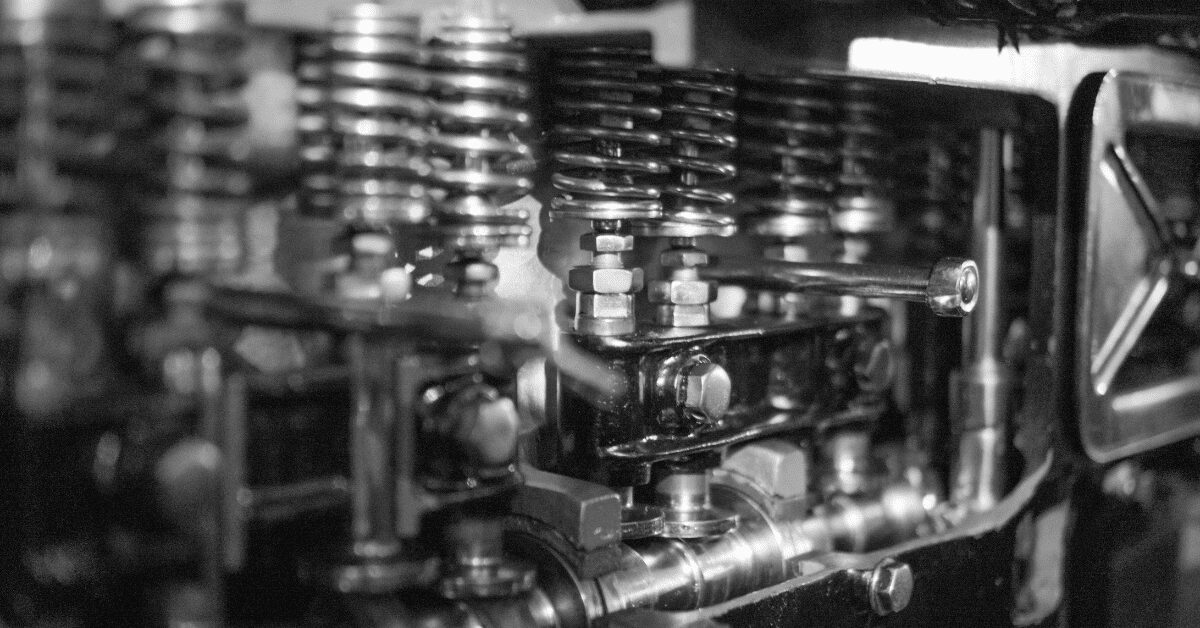

- Springs: Springs are used in various components of an aircraft, such as the landing gear and control systems. Stainless steel wire is an ideal material for springs due to its strength and resistance to corrosion. These properties ensure that the springs maintain their strength and shape, even after extended use.

- Fasteners: Fasteners are used to secure components and structures within an aircraft. Stainless steel wire is used in the manufacturing of fasteners due to its strength and resistance to corrosion. This ensures that the fasteners remain strong and reliable throughout the life of the aircraft.

- Safety Wire: Safety wire is used to secure bolts and other fasteners to prevent them from loosening or coming undone during flight. Stainless steel wire is an ideal material for safety wire due to its strength and resistance to corrosion. This ensures that the safety wire remains strong and reliable, providing an additional level of safety for the aircraft.

- Exhaust Systems: Stainless steel wire is used in the manufacturing of exhaust systems for aircraft due to its high temperature resistance and durability. The exhaust systems must be able to withstand the high temperatures generated by the engines, as well as the corrosive gases and fluids generated during operation.

In conclusion, stainless steel wire has many applications in the aerospace industry due to its unique properties, including strength, corrosion resistance, and durability. Its use in aircraft wiring, control cables, springs, fasteners, safety wire, and exhaust systems ensures the safety and reliability of aircraft. As the aerospace industry continues to advance, stainless steel wire will remain an essential material in the manufacturing of aircraft components and systems.