STAINLESS STEEL FINE WIRE

Stainless Steel Fine Wires Overview: Uncovering the Mysteries of SS Fine Wire

Stainless Steel Fine Wires combine strength, flexibility, and corrosion resistance. Therefore, they are ideal for a wide range of applications. Moreover, these wires are designed to meet strict industry standards, ensuring both precision and durability. Furthermore, their excellent conductivity makes them suitable for electronics, medical, and industrial uses. With rigorous quality control and advanced manufacturing processes, they consistently deliver reliable performance. As a result, choosing stainless steel fine wires ensures long-lasting solutions that exceed expectations, even in challenging environments.

In India, many manufacturers produce stainless steel fine wires. However, Ambica Steels India Limited stands out as a leader. Consequently, the company has become a key player in the fine wire manufacturing industry.

Let’s learn more about these versatile wires!

What is SS Fine Wire?

SS fine wires are thin, strong, and resistant to corrosion. They are made from stainless steel, which is a combination of iron, chromium, nickel, and other elements. Therefore, these wires are tough and can resist rust and staining effectively.

Additionally, these wires are called fine wires because of their thin diameter. This unique feature makes them suitable for a variety of applications. For example, they are commonly used in industries like electronics.

Stainless Steel Fine Wire in India.

The demand for stainless steel fine wires in India has grown rapidly. As a result, Ambica Steels India Limited has emerged as a market leader. They consistently provide high-quality SS fine wires to meet industry needs. Moreover, these wires are widely used in sectors like construction, automotive, and healthcare. Their focus on quality and innovation ensures reliability. Consequently, Ambica Steels remains the preferred choice for durable and dependable stainless steel fine wires.

Ambica Steels India Limited – Steel Wires You Can Trust

Ambica Steels India Limited stands as a leading fine wire producer in India, and it is widely recognized for reliability and excellence. Moreover, with a strong focus on quality and advanced manufacturing techniques, they have earned trust across various industries. Furthermore, their sophisticated processes ensure that stainless steel fine wires consistently meet the highest standards. Consequently, their dedication to innovation and precision positions them as the preferred supplier for businesses seeking top-quality fine wire solutions.

Advantages of Stainless Steel Fine Wire

- Durability and Strength: Many industries rely on stainless steel fine wires due to their toughness. Moreover, these wires offer the resilience needed for demanding projects, ensuring long-lasting performance.

- Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion. As a result, SS fine wires can endure harsh weather conditions, making them ideal for outdoor and marine applications.

- Versatility: These wires are incredibly flexible and can adapt to various forms. Consequently, they are suitable for intricate shapes and designs, meeting the diverse needs of sectors like electronics and healthcare.

- Aesthetic Appeal: With a sleek and attractive finish, SS fine wires are perfect for architectural designs. Additionally, they enhance applications where aesthetics are a priority.

- Hygienic Properties: Stainless steel fine wires are easy to clean and maintain. Thus, industries such as healthcare and food processing benefit greatly from their hygienic characteristics.

- Temperature Resistance: These wires can withstand both extreme heat and cold. Therefore, they are a reliable choice for harsh environmental conditions.

Conclusion

Stainless Steel Fine Wires are versatile, durable, and reliable. Therefore, they are suitable for a wide range of applications. Moreover, their strength, corrosion resistance, and adaptability make them essential for industries like healthcare, electronics, and construction. Furthermore, manufacturers such as Ambica Steels India Limited consistently deliver premium-quality products. Consequently, businesses can trust these wires to meet their unique needs. By choosing stainless steel fine wires, you ensure high-performance and long-lasting solutions, even in the most demanding environments.

| Diameter (mm) | Tolerance (mm) | Tensile (N/mm2) | Packaging and Spool type |

|---|---|---|---|

| 0.150-0.250 | +/- 0.004 | 850 Max | DIN 125/160/200/US200(NS100)/NS5 |

| 0.260-0.400 | +/- 0.005 | 830 Max | DIN 200/250/US200(NS100)/US250/PT15/PT25 |

| 0.410-0.630 | +/- 0.007 | 800 Max | DIN 250/US 250/ DIN355 |

| 0.635-0.800 | +/- 0.009 | 780 Max | DIN 355/Pay-Pack Drums/Coil |

| Please check with us specifications not listed above | |||

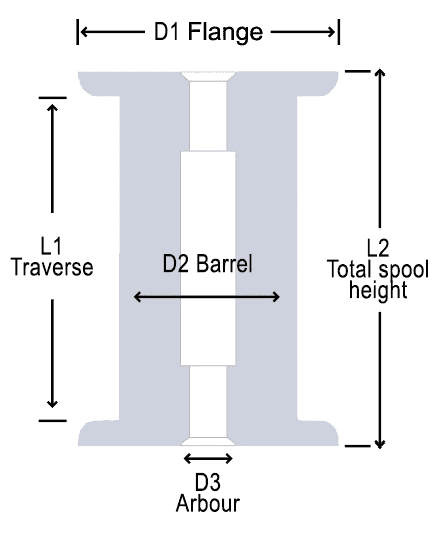

| Diameter(mm) | Spools | Spool wt (kg) | Wire Wt. Max (Kgs) | Spool Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | L1 | L2 | ||||

| 0.100-0.200 | DIN 125 | 0.15 | 3.00 | 125 | 80 | 16 | 100 | 125 |

| 0.100-0.250 | DIN 160 | 0.35 | 6.50 | 160 | 100 | 22 | 128 | 160 |

| 0.150-0.400 | DIN 200 | 0.70 | 14.00 | 200 | 125 | 22 | 160 | 200 |

| 0.250-0.630 | DIN 250 | 1.00 | 22.00 | 250 | 160 | 22 | 160 | 200 |

| 0.410-0.800 | DIN 355 | 2.00 | 45.00 | 355 | 224 | 36 | 160 | 200 |

| 0.150-0.400 | NS10/ US200 | 0.70 | 14.00 | 200 | 115 | 32 | 152 | 187 |

| 0.250-0.630 | US 250 | 1.00 | 22.00 | 250 | 160 | 32 | 160 | 200 |

| 0.20-0.35 | PT-15 | 0.64 | 15 | 180/200 | 95/108 | 30 | 200 | 227 |

| 0.25-0.70 | PT-25 | 1.05 | 25 | 210/225 | 108/128 | 32 | 248 | 278 |

| 0.15-0.30 | NS-5 | 0.22 | 5 | 120 | 54 | 16 | 130 | 150 |

| Pls check with us for specifications not listed above | ||||||||