Ambica offers its product in various packing options to suit customer requirements and end use. Great attention is devoted to the packaging process to guarantee the product’s arrival in a ‘mill fresh’ condition, with meticulous measures taken to ensure its sea-worthiness. Fine wires wound on spools are meticulously wrapped in stretch film before being placed in corrugated boxes. Additionally, they can be further packaged in wooden boxes or pallets, tailored to meet the specific requirements of our customers.

PACKAGING STANDARDS

Carrier

Coil with HDPE Packing

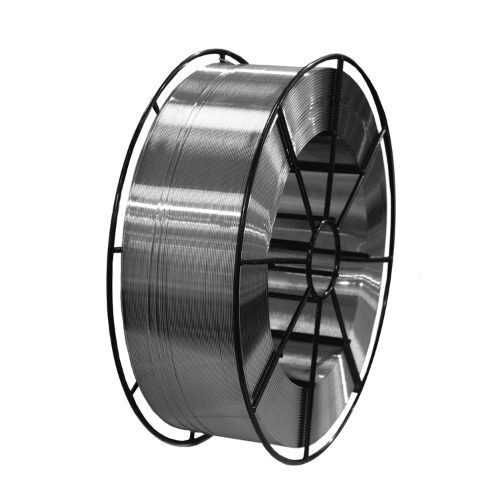

Metal Spool

Wooden Reel

Basket Spool

Paper Drum Pack

Basket Spool K 415

Layer Wound Coil of Paper Core

Plastic Spool-H400

Plastic Spool

Fine Wire Specifications

| Diameter(mm) | Spools | Spool wt (kg) | Wire Wt. Max (Kgs) | Spool Dimension (mm) | ||||

|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | L1 | L2 | ||||

| 0.100-0.200 | DIN 125 | 0.15 | 3.00 | 125 | 80 | 16 | 100 | 125 |

| 0.100-0.250 | DIN 160 | 0.35 | 6.50 | 160 | 100 | 22 | 128 | 160 |

| 0.150-0.400 | DIN 200 | 0.70 | 14.00 | 200 | 125 | 22 | 160 | 200 |

| 0.250-0.630 | DIN 250 | 1.00 | 22.00 | 250 | 160 | 22 | 160 | 200 |

| 0.410-0.800 | DIN 355 | 2.00 | 45.00 | 355 | 224 | 36 | 160 | 200 |

| 0.150-0.400 | NS10/ US200 | 0.70 | 14.00 | 200 | 115 | 32 | 152 | 187 |

| 0.250-0.630 | US 250 | 1.00 | 22.00 | 250 | 160 | 32 | 160 | 200 |

| 0.20-0.35 | PT-15 | 0.64 | 15 | 180/200 | 95/108 | 30 | 200 | 227 |

| 0.25-0.70 | PT-25 | 1.05 | 25 | 210/225 | 108/128 | 32 | 248 | 278 |

| 0.15-0.30 | NS-5 | 0.22 | 5 | 120 | 54 | 16 | 130 | 150 |

| Pls check with us for specifications not listed above | ||||||||

Spring Wire Specifications

| Diameter (mm) | Grade (AISI) | Tolerance (mm) | Tensile | Packaging | Surface Finish |

|---|---|---|---|---|---|

| 0.15-0.30 | 302,304,316, 17.7 PH | +/- 0.006 | ASTM A313/ JIS G4314 / EN 10270-3 / IS 4454 | DIN 125 /DIN160/ 200/250/ US 250 | Bright, Light oil |

| 0.31-1.00 | +/- 0.008 | DIN 200/ 250/ Coils/ SH460K /390K | |||

| 0.45-0.60 | +/- 0.010 | ( DIN 355/ SH390K/ SH460K/ 20"/ 22"/ 30"/ Metal Reels Coils ) | Soap/ Stearate Coated |

||

| 0.61-1.60 | +/- 0.015 | ||||

| 1.61-3.00 | +/- 0.020 | ||||

| 3.01 & Above | +/- 0.025 | Coils |

Cold Heading Wire Specifications

| Diameter (mm) | Grade (AISI) | Tolerance | Tensile (N/mm2) | Packing |

|---|---|---|---|---|

| 0.80-2.00 | 304/L, 316/L | DIN h9 | 600-750 | Coils/ Pay- pack Drums |

| 2.01 & above | 550-700 | Coils/ Pattern laid Coils | ||

| 0.80-2.00 | 302HQ, 304HC | DIN h9 | 500-650 | Coils/ Pay- pack Drums |

| 2.01 & above | 450-630 | Coils/ Pattern laid Coils | ||

| 0.80-2.00 | 410, 430, 434 | DIN h9 | 500-700 | Coils/ Pay- pack Drums |

| 2.01 & above | 450-600 | Coils/ Pattern laid Coils | ||

| Please check with us for specifications not listed above | ||||

Electro Polish Wire Specifications

| Diameter (mm) | Grade (AISI) | Tolerance | Tensile(N/mm2) | Packing |

|---|---|---|---|---|

| 1.40-3.00 | AISI 304,304L,316,316L,204Cu etc. | DIN h9 | 750-900 | Coils |

| 3.01 & above | 700-850 | Coils, Euro Coils | ||

| Please check with us for specifications not listed above | ||||

Redraw Wire Specifications

| Diameter (mm) | Grade (AISI) | Tolerance (mm) | Tensile (N/mm2) | Packing |

|---|---|---|---|---|

| 0.60 - 2.00 | 300 Series | +/-0.015 | 650-800 | Coils/ Pay-pack Drums |

| 2.01 & above | +/-0.020 | 600-750 | Coils/ Pattern laid Coils | |

| 0.60 - 2.00 | 400 Series | +/-0.015 | 500-650 | Coils/ Pay-pack Drums |

| 2.01 & above | +/-0.020 | 450-600 | Coils/ Pattern laid Coils | |

| Please check with us for specifications not listed above | ||||